Why OptiMIM

Unparalleled Metal Injection Molding Expertise

We are proud to employ many of the world’s most experienced MIM specialists. It means we can work with you from initial idea to final component, giving you the benefit of our know-how at every stage.

So with OptiMIM, you can create better components, for less cost, faster.

State-of-the-Art Metal Injection Molding Technology

We’ve built our MIM capability to deliver the highest quality small metal components at scale. It means we can offer outstanding levels of chemistry control, strength, and density across a wide range of alloys. And we can do it at virtually any volume.

Ultimately, it means we can deliver the components you need to drive your products forward.

The Right Alloy for the Job

There are a wide variety of materials available for metal injection molding—from stainless steel to tungsten alloys to super-alloys such as cobalt-chromium.

But it doesn’t stop there. Our experts can also create custom alloys to deliver the right balance of performance and cost for your products. So you get components precisely suited to your needs.

Better Performing Parts and Greater Consistency

On every project, we aim to deliver more consistent parts, more efficiently, at lower costs. Our goal is to do away with the expenses associated with secondary processes such as machining, achieving net-shape the first time.

So we build molds that are more efficient for high-volume production and put in as much complexity as needed up front to avoid costly machining and secondary operations.

Greater Design Freedom

We’ll help you integrate and consolidate multiple components into a single molded piece—reducing the need for multiple suppliers and decreasing processing and assembly costs. (You’ll also get parts that are stronger, more cost-effective, and closer to the original design intent.)

As a process, MIM frees designers from the traditional constraints of trying to shape stainless steel, iron, copper, titanium, and other metals. Simply, it creates new opportunities to improve performance and lower costs.

The result is greater freedom for designers and better products for your customers.

Why Industry Leaders Choose OptiMIM

The More Challenging, the Better: Bring Us Your Problems – the Most Demanding Industries Do

- Automotive: From turbochargers to sensors

- Defense: High-performance components across missiles and ordinance

- Consumer Electronics: High volume, fast development cycle components

- Firearms: High-precision fire control components, optics and more

- Medical/Dental: Disposable and reusable medical devices

No Guessing: Upfront Transparency Backed Up with Evidence

- Design for Manufacturing (DFM) optimizes manufacturability, preserves functionality, and reduces overall part cost.

- We predict the tolerance capability of what the MIM process can deliver with PCPK modeling.

- With OptiMIM’s specialized processes, you know what you’ll get from any project right from the start.

Get Complete Control: From Feedstock to Sintering and Everything in Between

- We make our own feedstock and can tune it to your precise requirements.

- We optimize the entire MIM process to achieve the best tolerances and material properties.

- Get predictability beyond the project—because our dimensions remain consistent across production runs.

- Unlike other suppliers, we manage every variable and leave nothing to chance.

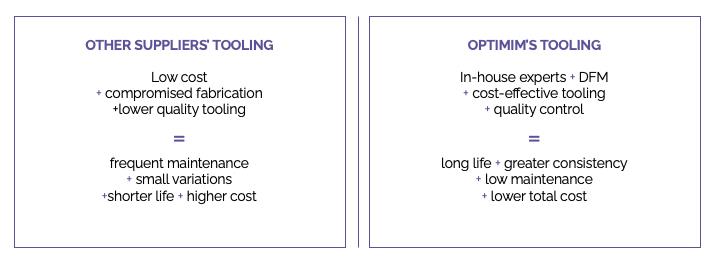

Longer Life, Less Variation: The Tooling Equation for Better Results

Discover Superior MIM Technology

In today’s demanding industries, average performance is simply not an option. To create truly class-leading products, only the highest performing components will do. Simply, good enough isn’t good enough.

OptiMIM uses state-of-the-art metal injection molding technology to create high performing small precision metal components to almost any level of complexity and at virtually any volume.